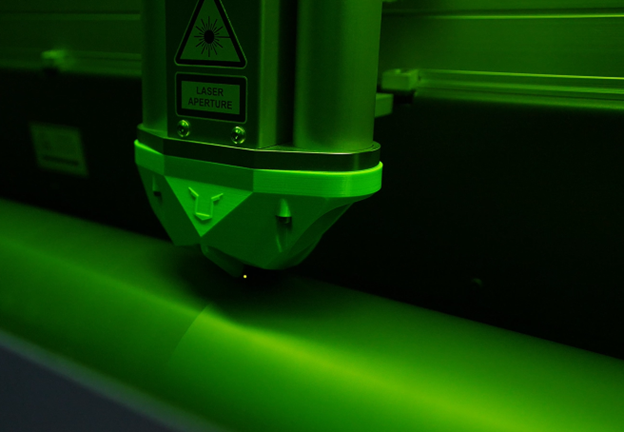

Introducing Anilox Laser Technology

Anilox laser technology is the first laser which does not damage the Anilox. The laser output is adjusted above the evaporation threshold of the contamination yet remains below the damage threshold of the ceramic layer.

Latest XIR-MOPA technology

The specially designed optical structure and XIR-MOPA laser source maintain the integrity of your aniloxes’ structure and cell walls.

Benefits

-

No stress in ceramic surface

-

No risk for melting (no damage of the ceramic)

-

Minimal increase of surface temperature

-

No laser peak variation during cleaning process

-

Clamping without damage

See the engineering behind Apex precision

Economic & Environmental Advantages

Economic Impact

The Anilox Laser consumes less than 2 kW per cleaning cycle, making it significantly more cost-efficient than conventional deep cleaning methods.

Environmental Impact

The process generates virtually no waste, as the contamination is thermally decomposed by the laser. The only maintenance requirement is the periodic replacement of the filters.

The Science Behind Safe, Precise Cleaning

At the heart of our Anilox Cleaning Service lies a laser system engineered for precision, developed in close collaboration with Anilox experts to meet the highest industry standards. Here’s how it operates:

Calibrated, Contaminant‑Focused Removal

After extensive R&D, we’ve discovered that contaminants like ink and polymers can be vaporized cleanly from the ceramic surface—without harming the Anilox cell structure—through a meticulously controlled laser technique.

Custom XIR‑MOPA Laser Source

Standard lasers lacked the pulse stability required to avoid micro-cracks. We partnered with our laser-source manufacturer to tailor a solution, resulting in the development of the XIR‑MOPA laser.

Sensor-Driven Precision Control

Our system continually monitors and adjusts all critical parameters—pulse power and width, frequency, focus shaping and distance, and Anilox rotation speed—to ensure safe and consistent cleaning.

Proven Durability & Reliability

After thorough testing, the laser cleaning technology performs safely—even after hundreds of cycles on the same Anilox sleeve—maintaining precision and structural integrity.

Industry-Endorsed Excellence

Oerlemans, of the OPAC Group, tested a predecessor model (AL1500) extensively and declared it “the most effective and safest system available worldwide.” This testimonial underscores our technology’s proven performance and sustainability.

By transforming laser cleaning into a reproducible, damage-free process, our technology helps turn printing from an interpretative art into a predictable science—maintaining ink volume, reducing setup time, minimizing waste, and delivering consistent, high-quality results.

AL machine, available in sizes S, M, and L

The AL‑Series from Lion Lasers offers precision-engineered, damage‑free laser cleaning systems tailored to meet the needs of label, small‑web, and mid‑web printing operations. With thousands of successful cleanings, these machines consistently deliver superior results—even on high line‑count anilox surfaces—with no damage after over 250 cleanings.

Mid‑web laser cleaning system

Available machines specs:

- Anilox sleeves dimensions

- Roller dimensions

- Roller weight

⚠️ Availability Notice: Anilox Cleaning Services are currently available only in the European market.⚠️

Request Your Quote for Anilox Cleaning Services

Available exclusively in Europe

Fill out the form below and our team will provide you with a customized quote tailored to your anilox cleaning needs. One of our specialists will be in touch shortly to discuss your requirements.